Working With Brass

While sometime I use stainless steel wire for linkages I most often use brass. It is very workable for most skill levels, generally has sufficient strength for automata projects and is not subject to corrosion. It is easy to solder and generally available through craft or hobby stores.

Sanding and Shaping

I use brass rods for pins and small shafts on just about all my projects. One of the good things about brass is it's workable with common shop tools. I have a small bench sander dedicated to working with brass. It has a fine oxide belt which I use to chamfer pins, clean the ends of rods coming from the cutout saw, and shaping brass sheets to make linkage arms to embed into characters.

Cutting

I use a Proxxon cutoff saw with a 3" abrasive cutting wheel for cutting larger rod diameters. It is shown below. It has been a real time saver in my shop as I used to cut these pieces my hand with a hacksaw! Smaller rods, like 1/16" and smaller, I cut with pliers and clean the ends on the bench sander.

Soldering

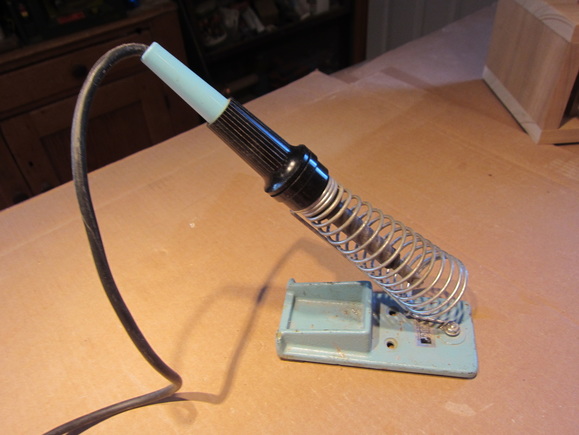

When it comes to soldering I'm old school. I prefer to use a an electric soldering iron over the newer butane gas burners available. Rightly or wrongly I feel I have better control over where the heat goes this way. I use a 100W Weller iron and manually apply soldering flux with a brush. Often a touch is all that is needed to join brass components. I do have a smaller iron, lower wattage, but do not use it often.

Bending

I hand bend brass wire linkages by hand using two pair of pliers. I use snub nose and needle nose pliers together. Get pliers with grooves on the faces to grab the small diameter brass stock. Often needle nose pliers have smooth faces and can result in brass stock sliding around as you try to bend it. I make right angle bends with the snub nose pliers and my hand using the plier's edge to eyeball 90 degrees.

Extra long needle nose pliers can be useful to bend links during assembly under the top plate of automata pieces, but be gentle, some of these pliers aren't strong enough to resist bending themselves. I often use multiple pairs of pliers to connect and bend links during assembly.

Extra long needle nose pliers can be useful to bend links during assembly under the top plate of automata pieces, but be gentle, some of these pliers aren't strong enough to resist bending themselves. I often use multiple pairs of pliers to connect and bend links during assembly.