|

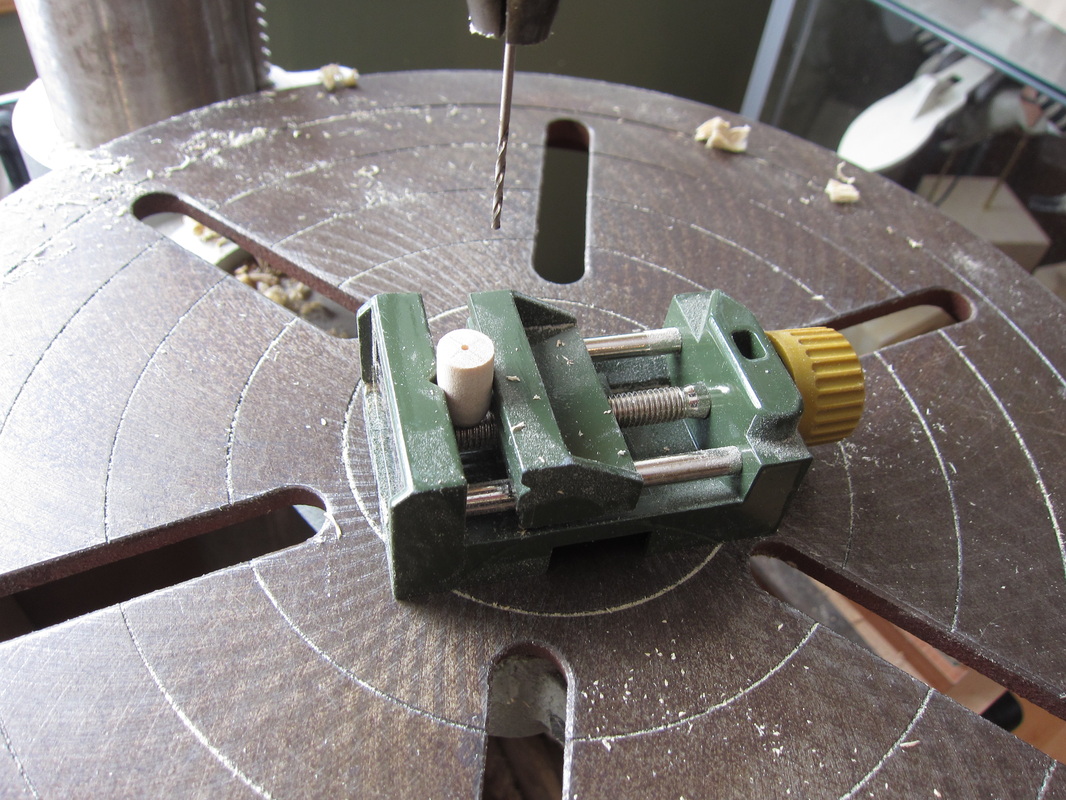

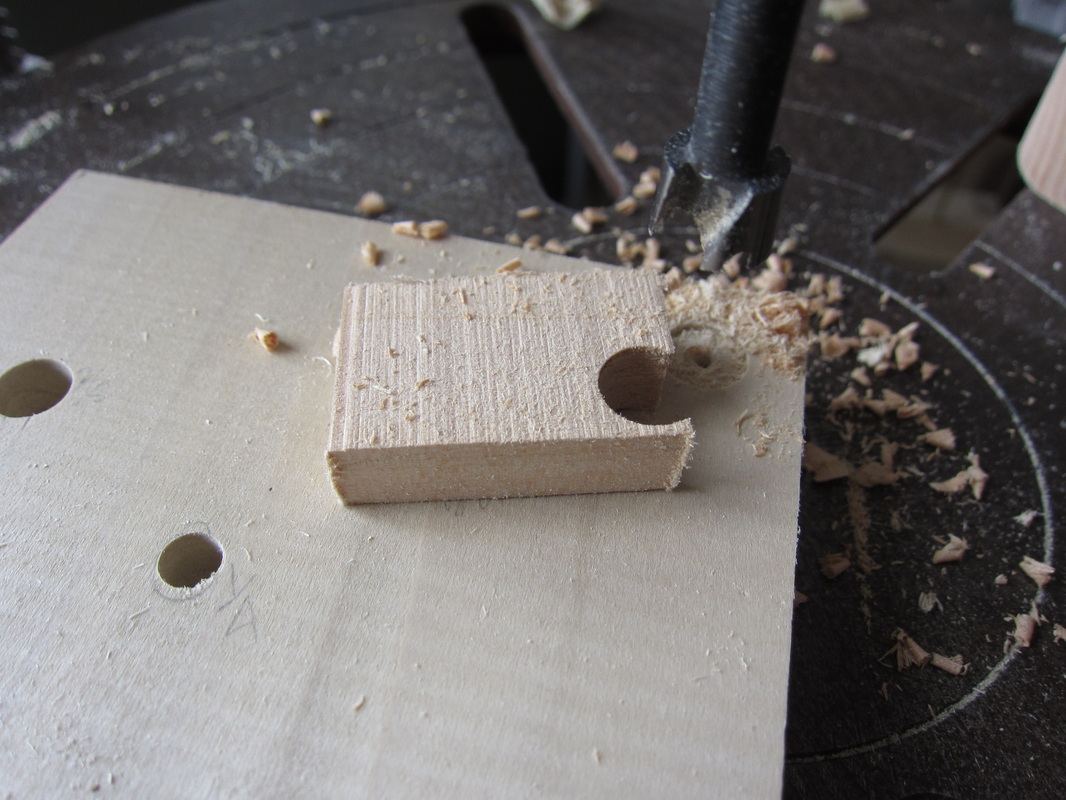

Well, it seems I can build a small seagull that moves his head! Here is how I did it. Start with a 7/16" dowel and round off the end. This is going to be the top of his head. Cut it to length, about 3/4", and drill a 1/16" hole into the centre of the bottom. This will be where the rod to swivel the head will go. Make the beak starting with drilling a 7/16" hole in a piece of basswood. This will provide the curved surface which will be glued to the dowel rod. Cut the beak shape from the block contouring the edges before gluing to the dowel. Into a block drill a 5/64" hole for the head and two 3/32" holes for the legs and cut out the shape for the body of the gull. Make a horizontal cut dividing the top and bottom of the body at the widest point of the body. Dig out a 5/16" deep bowl in the lower part of the body. Solder a small piece of 1mm brass wire around a 1/16" rod which will turn the head. Leave the legs wide enough to receive a 1/16" drive rod. Insert one 3/32" tube into one leg hole and a solid bar into the other. Bend a small offset in the crank and trim the end so it does not hit the upper half of the block, but merely touches it. Glue the body back together. Slide the head on the post and test the mechanism. Finally carve the rounded shape of the of the gull from the block. Here is the finished gull waiting for paint and addition to the automata mechanism!

0 Comments

I have had folks ask about the leak spout or blob in the "Call Before You Dig" automata. It is made from 12 pieces of shaped basswood glued onto a wooden plug. The center four create a square shape at the bottom. There are 4 more on each side, and 4 more glued into corners created. The individual drops were rough cut on the band saw and sanded to shape.

I chose gold to reassemble finished petroleum products since that was the segment I worked in . Black wouldn't have shown the detail well. What's a dock without a seagull? The answer. Not so realistic. So having designed a gull this week I am off to see if I can make it all come together in the shop this weekend. The challenge is that the seagulls, yes multiples, will only be 2" tall and seeing that it is an automata they must move. (Al's rule... if it's gonna be a part, impart some motion!).

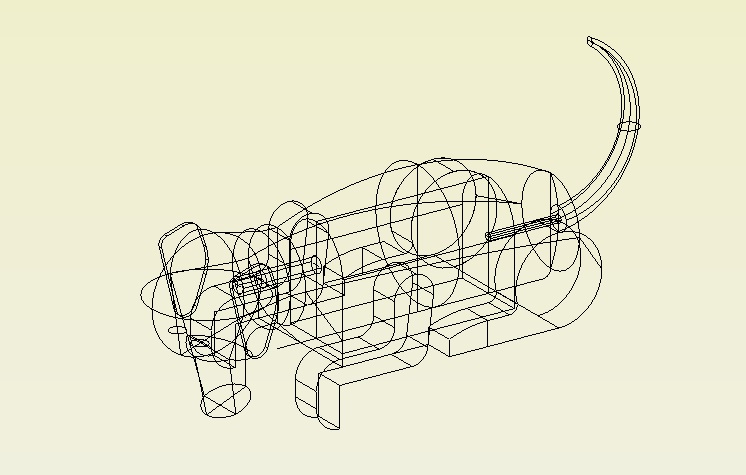

I have settled for a fairly simple turn of the head, but I want to hide the mechanism from sight. Therefore the design has the activation rod coming up inside one of the legs. I will use a 1/16" rod through a hollow brass tube acting as a leg, at least that is the plan. His legs might be a bit chunky, but things are allowed to be whimsical. I will cut and hollow out the body for the linkages and glue it together before final finishing. Who knows if I can make my fat fingers do this, I might try a moving beak! (That was typed with unbridled optimism. I may have to eat crow, or maybe even gull on that one.) If it doesn't work... well, at least I will know my limit. I'll take some photos along the way for posting! As allegedly the worst snow storm since 2009 in Toronto passes by outside the window I sit in the comfort of my office and design automata! I expect we are in for 25 to 30 cm. It's not he snow that's bad but rather the behaviour of some motoring folks out there. The photo is a wire frame sketch of a dog that is part of my next piece as it comes off my CAD system. I will use the drawing as a template to cut the block from which I will carve Rover - or whatever his name will be! He will be laying down peering over the side of a structure and his his will turn back and forth scanning for something while his tail also wags enthusiastically. The internal mechanism is not shown in the drawing however the shaft passages and the shape of the internal cavity are visible. A similar sketch for another component of the automata is not quite finished yet. "Rover" will be about 6-1/2" long and 2-1/2" tall. I suspect that after a few slips with the carving knife he will end up a mongrel rather than a pure bread.

After what seemed to be way to frustrating for it's level of complexity the "Call before You Dig" automata is completed. The finishing touch was installing some stainless cable and miniature crimps from the beading world to make Fred the Fainter resurrect himself after his shock. I have discovered my fingers are way to fat to ever be a beader!

I am currently building the website pages and video for the piece and will be posting soon. |

Why Automata?Automata is a creative blend of my life interests , engineering, art and woodworking. Archives

July 2022

Categories

All

|

RSS Feed

RSS Feed