|

The Rat Co. employee population took a big step forward today with continued recruiting (carving) of several new characters. Here they are seen as a collection of components in progress grouped with the original Rat Co. CFO. The pyrography is omitted on the body shapes where the arms will be attached and will be completed later. Arms and tails are custom fit as the character is fitted into the automata so their positions look realistic for their environment.

0 Comments

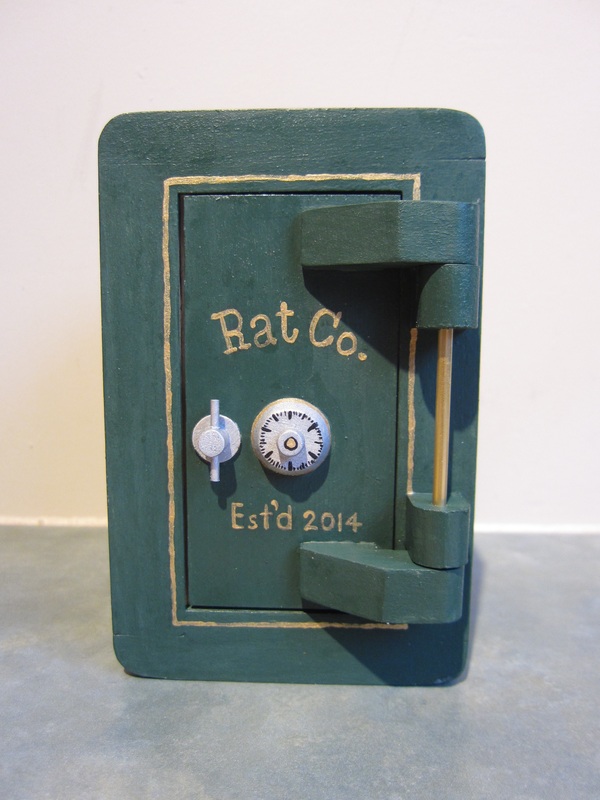

I little time this morning, morning news on in the background, and the Rat Co. vault gets paint!

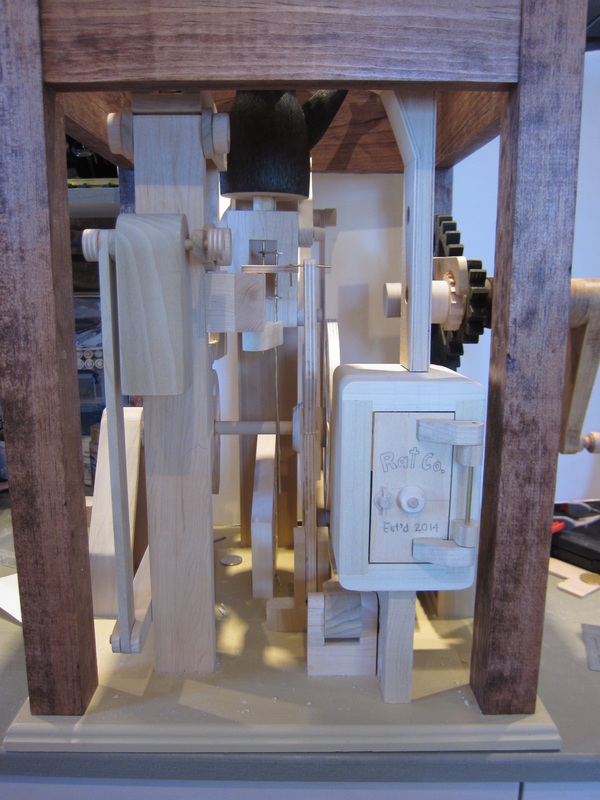

The vault is 3-1/2" wide, 5-1/2" tall and 3-1/2" deep. A few productive days in the shop have yielded a coin chute and vault for the latest automata project "Rat Co.". Obviously Rat Co. needs a safe place to keep it's money collected from the streets, so they have a company vault to store their booty. Here is the vault before painting, with a potential lettering design penciled on. The vault has a plexiglass panel on the rear to observe the size of the "take". Inside you can see an oversized door latch. It is a magnetic latch that requires a rare earth magnet to open the door. By placing a magnetic on the front of the door near the latch, it pulls open the stop and allows you to open the door. These latches are normally used on larger cabinets. One use is to keep children from accessing kitchen cupboards where cleaners are stored. I thought it was a cute gimmick for the "Rat Co." company safe so I squeezed it in. Here's the vault being test fitted in its future position in the automata project . You can also see the coin chute that delivers coins into the slot cut in the top of the vault. Here is a view of the top of the coin chute where Norton pulls in coins and drops them into the chute. The top plate has been removed to take this photo.

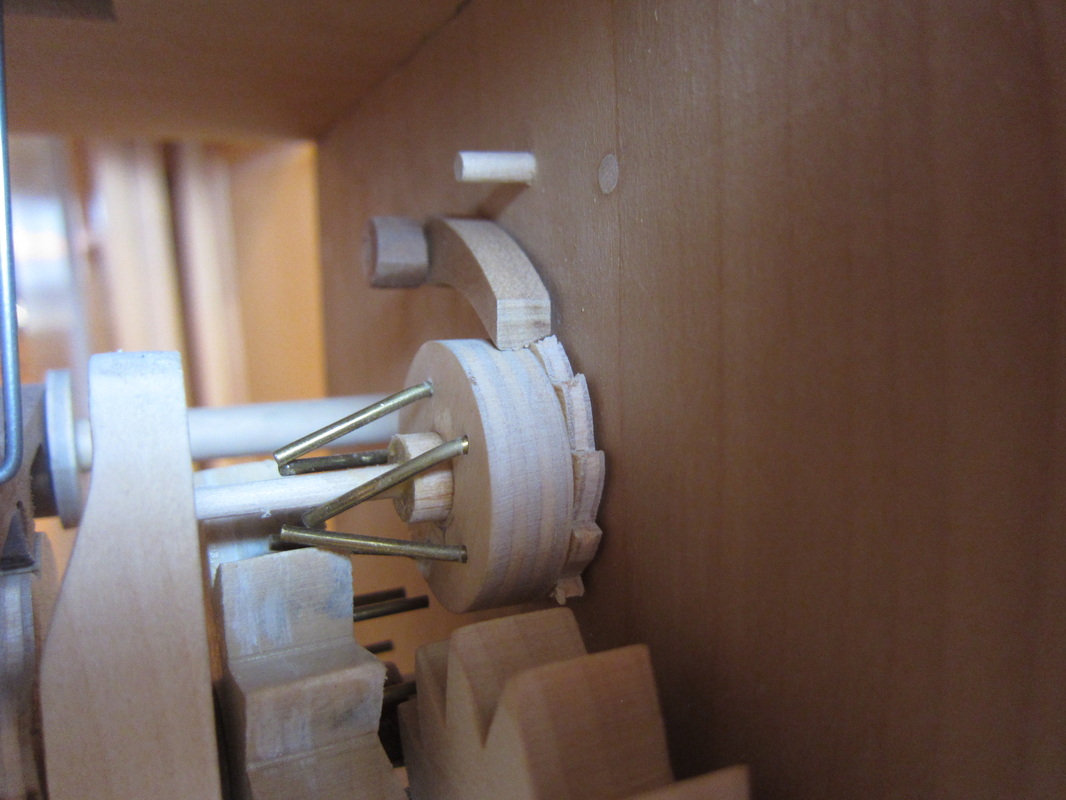

I always tell clients and visitors that automata are not children's toys. Nonetheless some seem to find their way into the hands of an unsupervised child. (Remember when you used to crank things as fast as you could? I do!) Anyway, as I finish up my current work I am planning the reconstruction of a piece that has received some overenthusiastic operation. I have learned from this though. Looking back at this early piece I believe the design of my pinwheels and gears might have been a little lacking. Also, the action when the character in this piece lifts his arms and radio puts a fair load on the mechanism. The resultant damage is as shown below. Not only are the pins mangled, but the anti-reverse ratchet has been broken as users tried excess force to free thinks up. The teeth on the ratchet and the end of the pawl have been chipped away. You can also see where the pins rubbed heavily on the star wheel as they bent.

The fix? Cut the case open and put in a new drive train using hand cut gears along with a beefed up anti-reverse mechanism. I'll have to chalk it up to lessons learned... Even though I am any from the shop, I dragged my carving knife and Dremel along and managed to work in a little time and "branded" the handle for the current automata project. The name of the piece "Rat Co." is cut into the crank. Originally I considered a Canadian Loonie for the handle but it just seemed to large, so I decided to go with a nickel. A nickel also fits well with the theme in a different way since the beaver on the Canadian nickel is a member of the rodent family.

On the weekend the crank will be united with the automata project and I'll focus on finalizing the coin chute. Although still unfinished the villainous rat finally reveals himself. Drop a coin on the street and Norton, who behaves like a modern day Fagan, scoops it up and drags into the sewer. He is an agent of Rat Co. an underground operation that collects funding for the development of underground infrastructure. More infrastructure means more homes for rats! I'm taking a few days off, away from the shop. At this point his arm, the manhole and street pavement shown in the video requires painting. and several small rats are in production to join the CFO. I have yet to finalize the coin chute and safe.

For some unknown reason this particular piece has been a series of unexpected challenges. I have even needed to resize the manhole cover to ensure smooth operation. It must be the long winter here in Southern Ontario. Another 15 centimetres of snow this weekend! Al Heres a photo, a little fuzzy, from my phone with the CFO sitting where he will eventually reside in the current work. He looks so lonely I've been inspired to add a few buddies for him. I still have not finished the construction as you can see from some protruding shafts in this photo. I suspect the space to the upper right of my friend will be filled with a safe; but you will have to wait for that.

Taking a couple of days out of the shop to maintain a proper perspective on the world, but will be back at it soon. Here is the CFO with a coat of paint, and money in hand waiting to be positioned on the final assembly.

Maybe he could spend some of that Lonnie on dental work! I decided to add a few additional minor characters into the current project. This little fellow is one character who will sit in the mechanism area. While he holds the lofty tittle of CFO (Chief Financial Officer), in this case he merely tracks and counts the coins collected from above. He is holding a Canadian "Loonie", a dollar coin about 1" in diameter. He is made from 11 assembled pieces. His feet, hands, and tail are maple, which is strong enough to handle details like shaping his toes, his eyes and nose are shaped from a 1/4" dowel, and the rest is basswood. His fur is cut with a pyrographic burner.

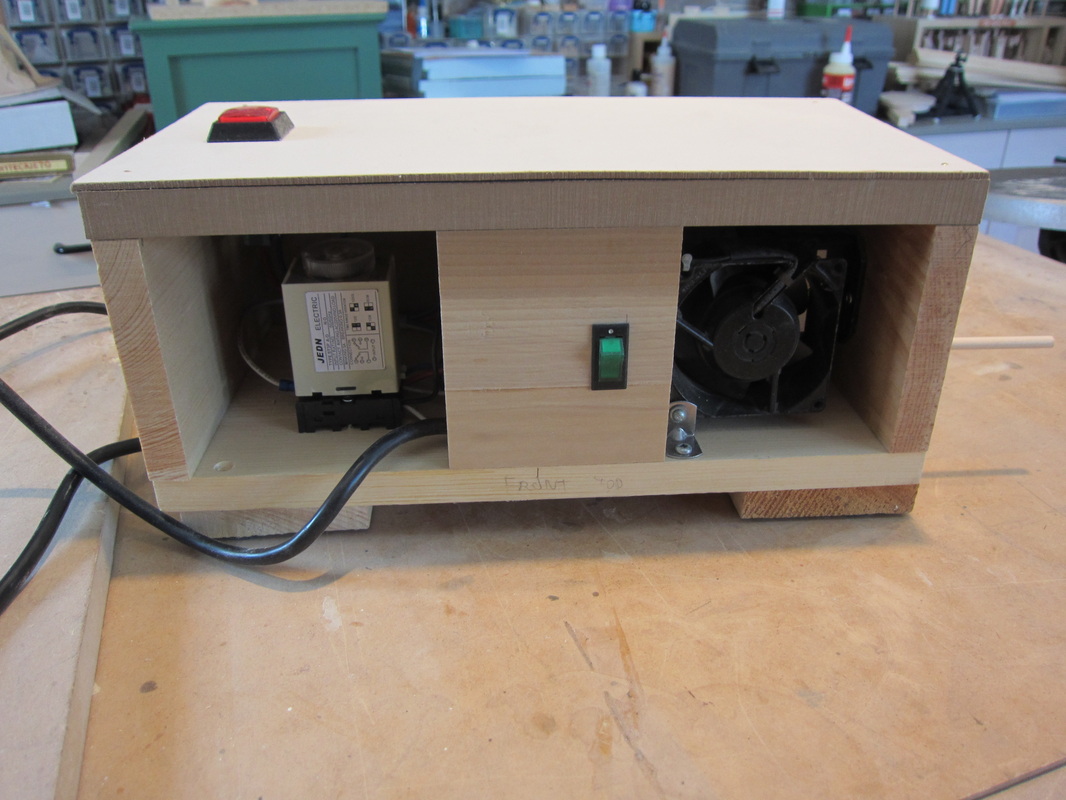

With the addition of two front teeth, a coat of paint and some eyeballs, he'll be ready assume his fiscal responsibility. When I display my automata at shows you can develop cramps from winding mechanisms. I would also rather talk to visitors than focus on turning cranks. I generally don't let visitors crank mechanisms until I determine they have the proper amount of respect for the work. My solution was to automate some pieces, have them not operate continuously, and not install permanent motors to try to stay true to the personal interaction a hand crack provides. The solution is a temporary driver I use for shows called "Conquergood Creative's Right Hand Man". The output shaft has a 1/4" dowel that pushes on the crank handle of the automata to make it work. It's important, of course, to have the centre line of the Right Hand Man aligned with the centreline of the piece being cranked. I use a shim plate under the automata or Right Hand Man as required to do this. The box has an adjustable timer so I can set the time to run for anywhere from seconds to minutes. There is a fan inside just to keep things cool and a big push button on the top to actuate it.

I have three of these so I can run several pieces at once. When someone is walking by all I have to do is push the button and the action draws them in. |

Why Automata?Automata is a creative blend of my life interests , engineering, art and woodworking. Archives

July 2022

Categories

All

|

RSS Feed

RSS Feed