|

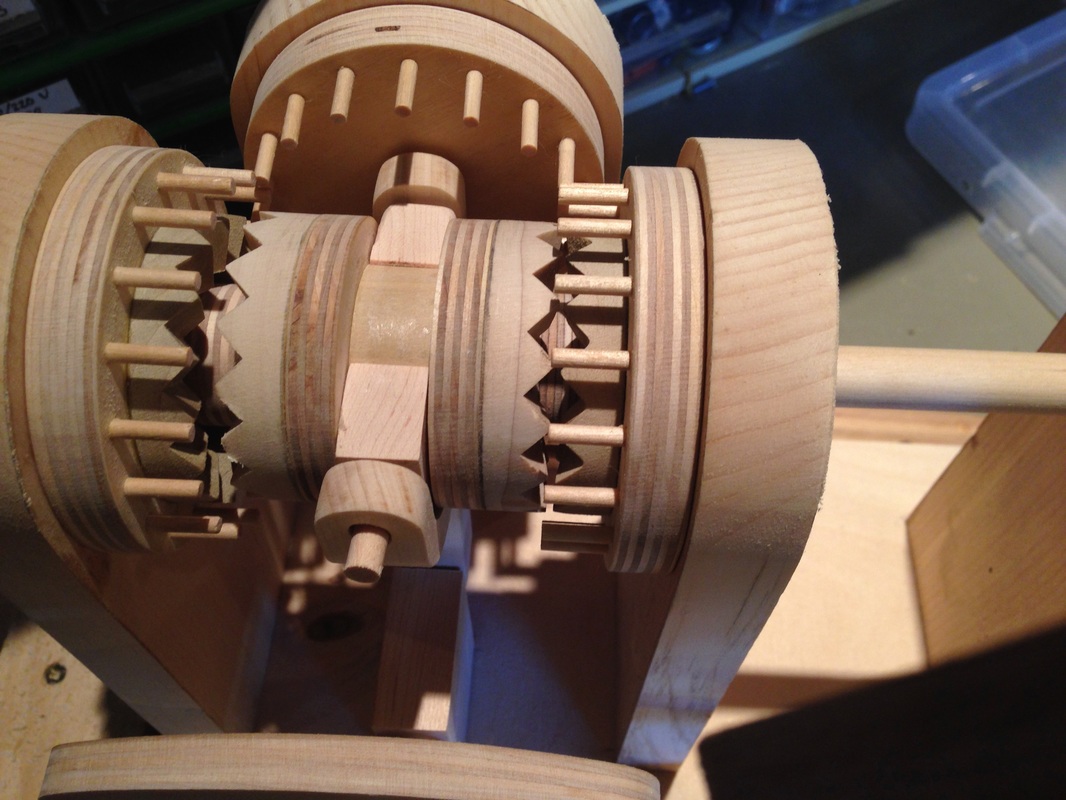

If you look at my previous blog you'd see that I was building a reversing clutch from an early patent sketch. Well Version 1 had a few issues, so I set out on Version 2. The biggest change was the clutch faces. I moved them a little closer together and went for a face to face direct contact ( more like the patent sketch) since Version 1 did not release well. After building a jig to router the clutch plates I was happy with the fit and appearance. After fit up the clutch movement seems to work fairly well. Here is a view of the new clutch components before assembly. Assembled, as shown below, the mechanics seems to work fairly well. I also had to relocate the reverse trip lever to a more optimum location. After all the rework, I was dismayed to find that even the load of moving the swing weight was enough to cause the clutch faces to open and fully disengage. Obviously my focus on an easy engagement for the clutch missed the small amount of load that would cause the beveled surfaces to open. Here's how Version 2 looked. So while the device may look cool, it has fallen well below my operating and reliability requirements as part of an automata project. So it is a sad day when I call it quits after investing a fair bit of time working on something, but it is clearly time to cut and run. I am now working an alternate mechanism design for my project. It was fun working on it, for a while anyway, until the frustration crept in.

4 Comments

Beth

11/6/2016 11:10:08 am

Hope you are having a better day with your gear issues. Frustrating I'm sure.

Reply

William Wigley

11/7/2016 07:03:03 am

Maybe the solution would be more friction between the clutches. You could possibly paint one side of the clutch with a coat of rubber cement, or something similar. Most clutches have some sort of friction material. Don't give up....think outside of the gear-box...so to speak.

Reply

Al Conquergood

11/7/2016 07:43:54 am

I'm sure that sometime in the future I will get back to making it work better, even just to demo the mechanism. I will likely go back to the original star design with a lot more play. Thanks for the encouragement though! 7/4/2024 03:56:37 am

Perhaps increasing the friction between the clutches could be a solution. Applying a coat of rubber cement or a similar material to one side of the clutch could enhance grip. Most clutches already incorporate some form of friction material, but this DIY approach might provide an additional boost."

Reply

Leave a Reply. |

Why Automata?Automata is a creative blend of my life interests , engineering, art and woodworking. Archives

July 2022

Categories

All

|

RSS Feed

RSS Feed