|

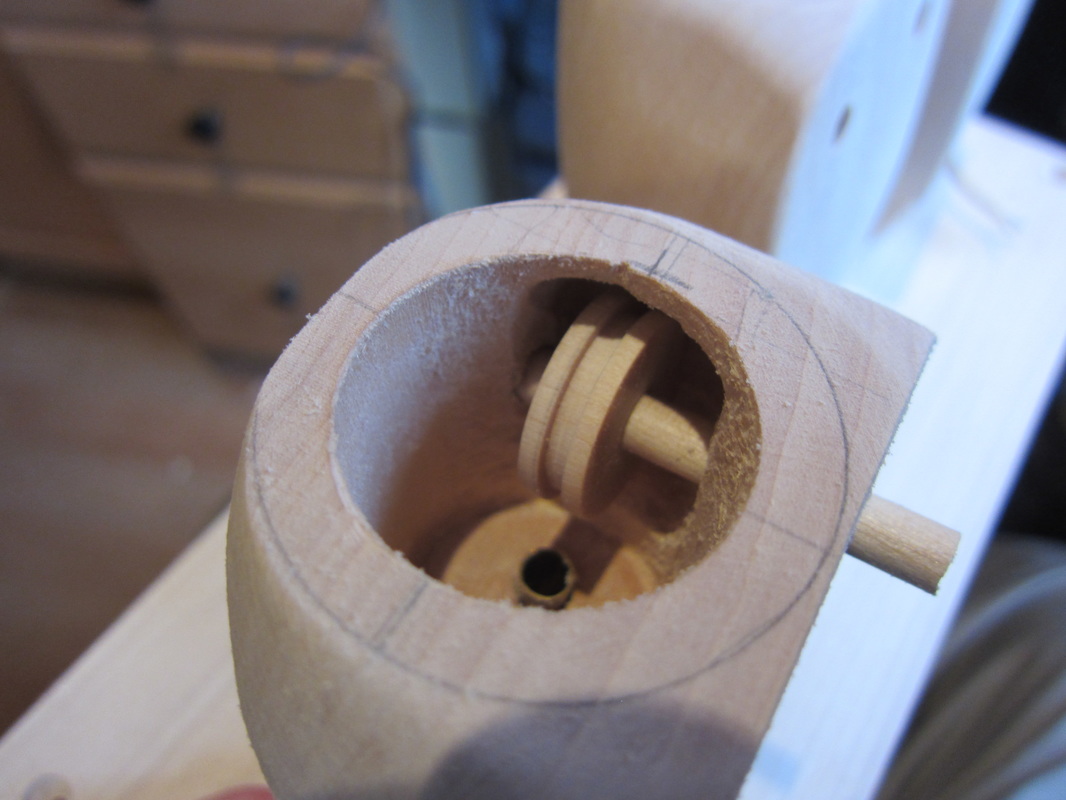

In the current piece an owl on the left side raises his wing to tap the centre owl on the opposite shoulder. Here's a photo to show the simple mechanism that will make this work. In the photo you can see a 1/4" dowel that extends through the back of the body. The wing will be glued onto the end of this dowel. The hole for the dowel has been drilled straight through the body before shaping. The front will be filled with a 1/4" plug and smoothed to match the chest, and should be invisible from the outside when completed. Enough length will be left on the inside of the front to act as a bearing surface for the front end of the dowel. I made a small wheel with shoulders on my lathe so a pull cable can wrap around it without coming off. The cable is not installed yet, but I will use a small screw to secure a looped stainless steel braid cable. I will coat the termination with a little epoxy to ensure it will not pull out. This is a little excessive. If the cable wheel is fixed in the correct position the termination will never feel much pull from the cable.

You can see a short lentgh of brass tube that is stuck in the top of the hole through the body. It is secured with CA adhesive. It will prevent the pull cable from abrading the wooden block. The last piece will be a little keeper wheel that will sit toward the back shaft, and bear on the inside of the body block. This will keep the dowel from sliding toward the back of the owl and maintain alignment of the cable over the hole and maintain the size of the bearing surface on the front of the shaft.

0 Comments

Leave a Reply. |

Why Automata?Automata is a creative blend of my life interests , engineering, art and woodworking. Archives

July 2022

Categories

All

|

RSS Feed

RSS Feed