|

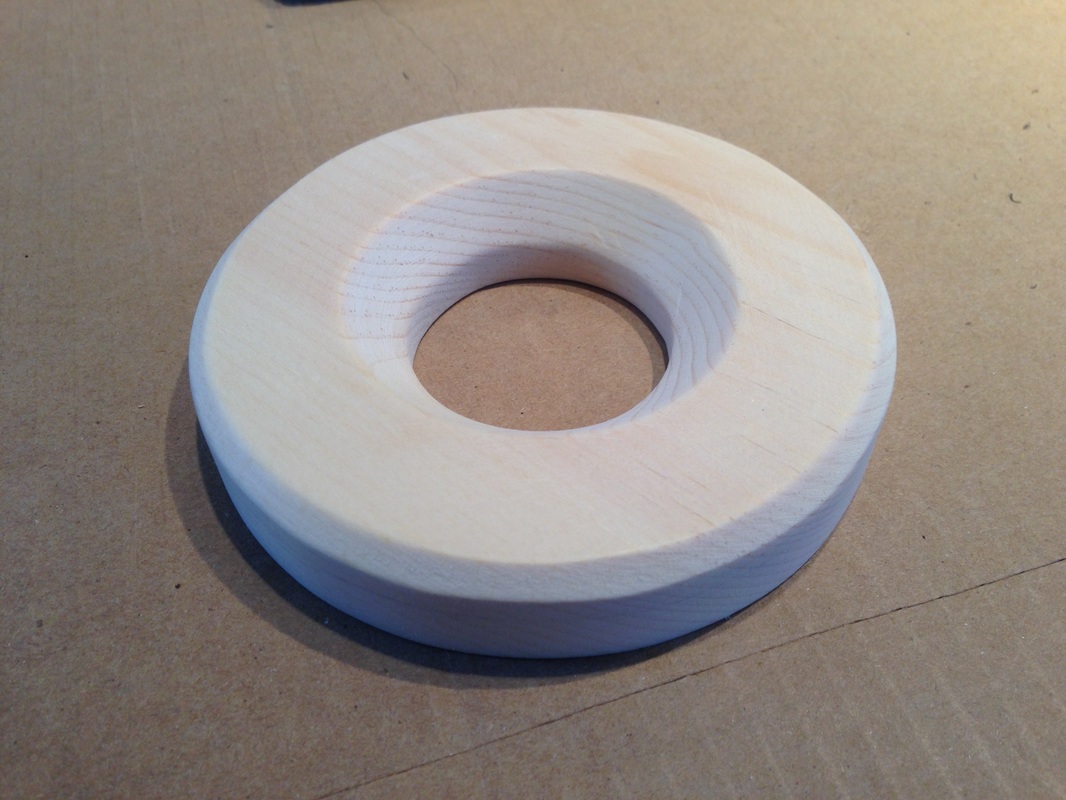

You know there are many times you wish you had a nice big lathe so you could whip something off, right? Then you start to think where would I put it and would I ever use it enough to justify it's existence. ( As if that ever stopped me from buying tools before!) But i've been fairly determined that I do not need a big lathe, but this project had two pieces that would be nice to turn and they are just to big for my little Sherline lathe. What to do? Well I could go over to my friend Jim's, a dedicated turner, and talk him into doing it. A fair solution but it is a way to go and he's busy enough himself. The setup to face mount the pieces seem excessive to me, so I put mind idle mind to work and came up with an ad-hoc solution. Usually I cringe when some says that! Here's the shape I needed to make two of. What dosen't show is an additional steep ring that is needed on the backside to have it fit snuggly into a tube. And here is how I did it. As I didn't need to remove much material to make the inside bevel I made a jig with a small plate the diameter of the inner hole and mounted on a large flat back. I clamped it in my drill vide and rotated it up to 45 degrees. Mounting an appropriate sized sanding drum in the drill press i could push the work into the drum while rotating the workpiece. A circle drawn on the face guided me to my final dimension. You have to keep aligning the vice on center with the drum as you go. Just go slow and steady. I put the outside bevel on my bench sander.

Not for everyone, but if you do try it, work slow and safe. It saved me a day, a few cups of coffee and some tale tales. I'l get them another time!

0 Comments

Leave a Reply. |

Why Automata?Automata is a creative blend of my life interests , engineering, art and woodworking. Archives

July 2022

Categories

All

|

RSS Feed

RSS Feed